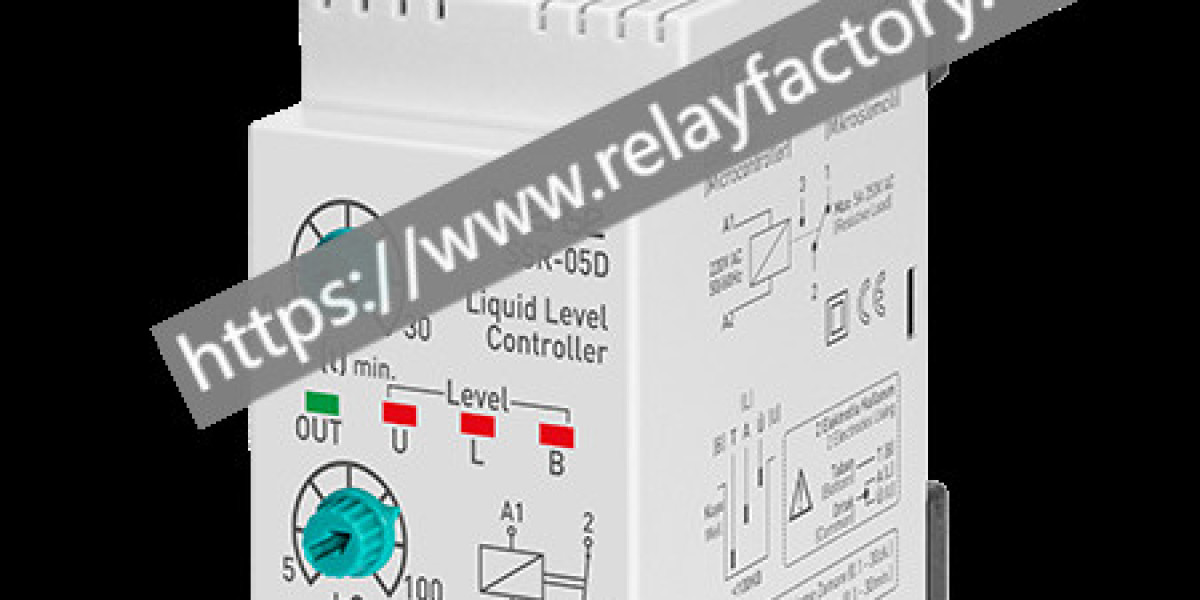

If machines could talk, your water tank would probably say, “Hey, I’m full—please stop!” Luckily, that’s where the Liquid Level Relay comes in. This clever little device is the translator between your liquid systems and your sanity. It quietly ensures that tanks don’t overflow, pumps don’t run dry, and your maintenance crew doesn’t lose sleep at night. In the world of automation, the Liquid Level Relay is that dependable friend who never forgets to turn off the faucet.

Think of it as a bouncer at a club—only instead of letting people in or out, it manages the flow of liquids. When the level gets too high, it says, “Alright, that’s enough.” When it gets too low, it nudges the pump and says, “Let’s top things up a bit.” This constant balance keeps everything in rhythm, from factory cooling systems to irrigation setups. Without it, your system might swing between Sahara-dry and Niagara Falls.

One of the great things about the Liquid Level Relay is that it doesn’t demand attention. No blinking lights, no dramatic beeping—just steady, silent control. It’s like that reliable employee who does everything right but never asks for a raise. You won’t notice it working, but you’ll definitely notice when it’s missing.

And installation? A breeze. You don’t need to summon a team of engineers or perform a ritual under the full moon. Most Liquid Level Relays fit neatly into control panels and connect easily to your existing system. Once set up, they just… work. Day after day. Week after week. Quietly managing the chaos of liquid dynamics with zero complaints.

Here’s the fun part: this small gadget is surprisingly smart. It knows when to act, how long to hold, and when to stop—all based on what your setup needs. Whether you’re handling water, oil, or chemicals, it keeps everything perfectly balanced. Think of it as the “zen master” of liquid management, ensuring harmony between your pumps and tanks.

Let’s not forget the safety angle. Overflowing tanks and dry pumps aren’t just messy—they can cause real damage. A Liquid Level Relay steps in before things go sideways. It cuts power to prevent burnout, turns devices back on at the right time, and ensures no unpleasant surprises mid-shift. Basically, it’s your system’s personal life coach, keeping every component calm and focused.

Even energy efficiency gets a boost. Since pumps only run when needed, you save power and reduce wear. It’s like teaching your equipment to take power naps instead of pulling all-nighters. Over time, that means lower bills, longer equipment life, and fewer “why is this machine smoking?” moments.

In short, the Liquid Level Relay is a small device with a big sense of responsibility—and a great sense of timing. It doesn’t brag, but it deserves a medal for keeping industrial systems clean, safe, and efficient. Every factory, plant, and facility that deals with fluids should have one—or a few dozen—on their team.

To find dependable Liquid Level Relays that bring balance to your operations (and a little peace of mind), visit www.relayfactory.net . You’ll discover practical designs, reliable construction, and solutions that work as quietly as they do effectively—no drama, just results.