Unlike traditional cleaning methods, which often rely on chemicals, abrasives, or labor-intensive processes, laser cleaning machine offer a modern alternative that ensures surfaces are treated accurately without physical wear.

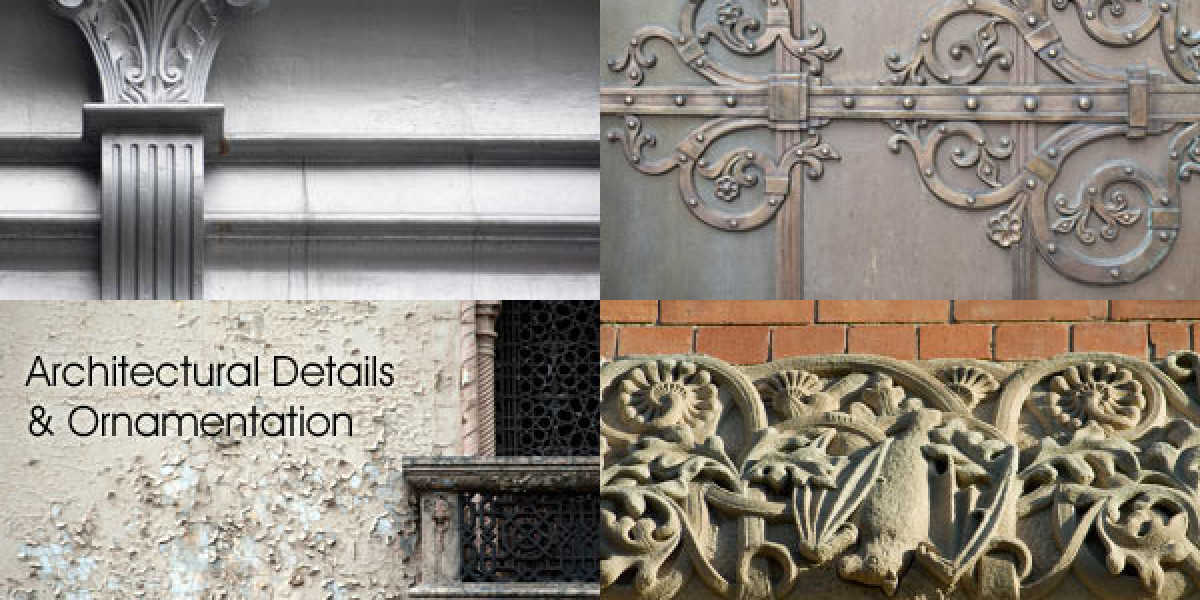

Industrial sectors, including automotive, aerospace, shipbuilding, and manufacturing, are increasingly adopting laser cleaning machines. These machines are capable of handling a wide range of materials such as metals, ceramics, plastics, and composites. The precision of laser cleaning allows operators to target specific areas without affecting surrounding surfaces. This capability is particularly useful for complex machinery components, delicate parts, and historical restorations where traditional cleaning methods could cause damage.

Laser cleaning machines come in different types and power levels, depending on the application requirements. Handheld units are often used for small-scale cleaning tasks, offering portability and ease of operation. On the other hand, industrial-grade systems are designed for large-scale operations and can be integrated into production lines for automated cleaning processes. These systems are highly customizable, allowing operators to adjust parameters like laser intensity, pulse duration, and scanning speed to suit specific tasks.

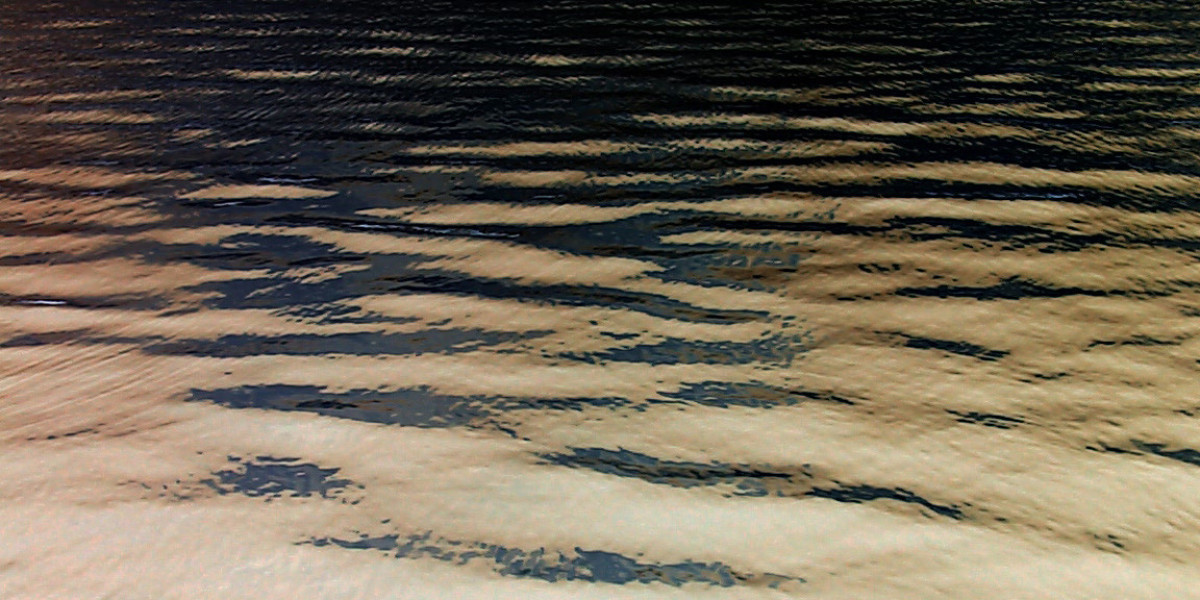

The mechanism behind laser cleaning is straightforward but highly effective. The laser emits short pulses of concentrated energy that heat and vaporize contaminants on the surface. Dust, rust, paint, and oil residues are removed in the process, leaving the base material clean and intact. The precision of the laser beam ensures minimal heat impact on the material, reducing the risk of distortion or damage. This method is not only efficient but also environmentally friendly, as it avoids chemical waste and reduces the need for water or abrasive materials.

Laser cleaning machines are also known for their ability to improve the longevity and performance of machinery. By removing rust, scale, and other residues from metal surfaces, these machines prepare surfaces for subsequent processes like welding, coating, or painting. This results in stronger bonds, better adhesion, and improved overall quality. In industrial settings, regular cleaning with laser machines can prevent corrosion, reduce maintenance costs, and extend the life of equipment.

In addition to industrial cleaning, laser cleaning machines are increasingly being used for restoration purposes. Historical monuments, sculptures, and delicate artifacts often require cleaning that preserves the original material. Traditional methods such as sandblasting or chemical treatment can be too harsh, risking irreversible damage. Laser cleaning machines provide a precise, controlled solution for these sensitive applications, allowing conservators to remove dirt, grime, and corrosion layer by layer without affecting the underlying structure.

Safety is another important aspect of laser cleaning machines. Modern systems are equipped with protective enclosures, safety interlocks, and automated controls to prevent accidental exposure to laser beams. Operators receive training to handle the equipment properly, ensuring that cleaning processes are carried out efficiently and safely. Furthermore, the controlled nature of laser cleaning reduces airborne dust and debris compared to abrasive or mechanical cleaning methods, contributing to a safer working environment.

The versatility of laser cleaning machines makes them suitable for a wide array of applications beyond traditional cleaning. In the electronics industry, they are used to clean delicate components without causing thermal damage. In automotive manufacturing, laser cleaning prepares surfaces for painting or welding, ensuring high-quality finishes. Shipyards and heavy industries utilize laser cleaning machines to remove rust and coatings from large metal structures, increasing operational efficiency and reducing downtime.

Maintenance and operational efficiency are key considerations when using a laser cleaning machine. Regular inspection of optical components, calibration of laser output, and monitoring of system parameters ensure consistent performance. Unlike traditional cleaning methods, which may require frequent replacement of abrasive materials or chemicals, laser cleaning machines have fewer consumables and lower long-term operational costs.

The future of laser cleaning technology is promising, with ongoing developments in laser sources, automation, and precision control. Advances in fiber laser technology, for example, have improved energy efficiency, increased cleaning speed, and expanded the range of materials that can be treated. Integration with robotic arms and automated systems allows for continuous operation in high-volume industrial environments, further enhancing productivity and reliability.

Laser cleaning machines have also become more accessible to small and medium-sized enterprises. Portable units and user-friendly interfaces make it possible for businesses with limited space or budget to adopt this technology. Training programs and technical support from manufacturers help operators maximize the machine’s potential while ensuring safety and optimal results.

In summary, the laser cleaning machine represents a significant advancement in surface cleaning and industrial maintenance. Its precision, efficiency, and versatility make it suitable for a wide range of industries and applications. By eliminating the need for harsh chemicals and abrasive materials, laser cleaning not only improves operational efficiency but also contributes to environmentally responsible practices. Regular use of laser cleaning machines can maintain equipment quality, extend its lifespan, and enhance the overall productivity of industrial operations.

Final Thoughts

The adoption of laser cleaning machine is transforming the industrial landscape by providing a modern, efficient, and environmentally conscious solution for surface treatment. From industrial maintenance to delicate restoration, these machines offer unmatched precision and control. As technology continues to evolve, the applications and benefits of laser cleaning machines will only expand, making them a critical tool for industries focused on quality, efficiency, and sustainability.