Understanding how the laser nozzle works, its design variations, and its impact on process quality is essential for achieving consistent and professional results in industrial and commercial laser operations.

Understanding the Role of a Laser Nozzle

A Laser Nozzle serves as the final exit point for both the laser beam and the assist gas. This component ensures that the assist gas—whether oxygen, nitrogen, argon, or compressed air—is directed precisely onto the work area. The nozzle’s geometry directly influences the quality of the cut or weld, the speed of processing, and even the lifespan of the optical elements in the laser head.

During laser cutting, for example, the nozzle not only delivers the gas but also forms a pressurized channel that helps remove molten material from the kerf. In welding, the same principle applies—the nozzle ensures a stable gas shield that prevents oxidation and contamination of the weld pool.

The Laser Nozzle therefore plays a dual role: it controls the quality of the laser beam’s interaction with the material and protects the overall system from potential damage.

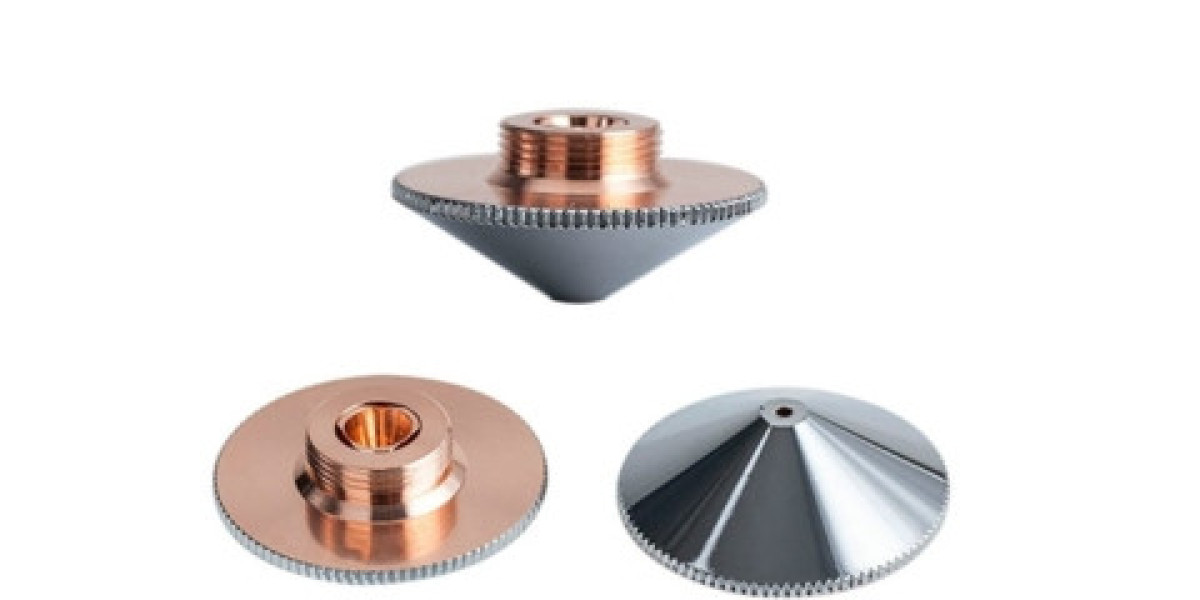

Materials and Manufacturing Precision

Laser nozzles are usually made from high-grade copper or brass due to their excellent thermal conductivity and durability. Copper nozzles are preferred for high-power applications, as they can withstand intense heat and maintain consistent performance. Brass nozzles, on the other hand, are more economical and are often used in lower power setups.

The internal design of the nozzle is precisely machined to ensure perfect alignment with the laser beam path. Even a slight imperfection or misalignment can cause a deflection in the beam, leading to inconsistent cuts or welds. The nozzle’s tip is polished and coated to minimize spatter buildup and maintain a clean gas flow.

Modern manufacturing techniques, such as CNC precision machining and laser-based calibration, are used to create nozzles that meet strict tolerances. These high-precision designs ensure consistent gas flow, reduced turbulence, and optimal energy transfer from the laser to the material.

Types of Laser Nozzles

The Laser Nozzle is available in different designs based on the process and machine type. Common variations include:

Single Nozzle: Used for standard cutting or welding applications, where a single jet of gas is sufficient for debris removal and material protection.

Double Nozzle: Used for enhanced gas control, especially in thicker materials or complex weld geometries. The dual design provides better coverage and more stable pressure distribution.

Conical Nozzle: Designed for precision tasks, such as fine engraving or thin metal cutting, where gas focus and direction are crucial.

Flat Nozzle: Often used in laser cleaning or surface treatment, ensuring even gas distribution over a wide area.

The choice of nozzle depends on parameters like beam diameter, power level, assist gas type, and the specific industrial application.

The Importance of Nozzle Distance and Alignment

Even with a high-quality Laser Nozzle, the performance largely depends on its distance from the workpiece and its alignment with the laser beam. The nozzle-to-workpiece distance determines the gas pressure at the cutting or welding point. If the distance is too large, the gas jet loses its efficiency, leading to poor edge quality or incomplete material removal. If the distance is too small, spatter may hit the nozzle, causing clogging or thermal damage.

For precise operations, manufacturers often use automatic capacitive sensors to maintain an optimal standoff distance between the nozzle and the material surface. Proper alignment ensures that the gas jet is concentric with the laser beam, allowing the process to remain consistent across long production runs.

Gas Flow Dynamics in Laser Processing

The Laser Nozzle works in harmony with the assist gas to achieve optimal cutting and welding conditions. The gas pressure, type, and flow rate depend on the material and the process parameters.

Oxygen is used to promote combustion and increase cutting speed for carbon steels.

Nitrogen prevents oxidation and produces clean, bright edges, ideal for stainless steel and aluminum.

Argon is common in laser welding for creating an inert atmosphere and ensuring smooth bead formation.

Compressed Air offers a cost-effective solution for general-purpose cutting and cleaning applications.

The nozzle’s geometry influences how efficiently the gas stream removes molten metal and how well it protects the beam path. A poorly designed or worn nozzle can create turbulence, which leads to dross formation, uneven cuts, or poor penetration depth.

Maintenance and Cleaning of Laser Nozzles

To maintain high performance, the Laser Nozzle requires regular inspection and cleaning. Accumulated debris, spatter, or oxidation inside the nozzle can alter gas flow patterns and reduce processing quality.

Many manufacturers recommend using dedicated nozzle cleaning systems that use soft brushes or compressed air to remove residues without damaging the internal surface. Periodic replacement is also necessary since even minor wear can alter gas symmetry and cause beam misalignment.

A clean and well-maintained nozzle ensures stable gas flow, reduced spatter, and prolonged optical life for the laser head. Regular maintenance also minimizes downtime and ensures the laser system runs at peak efficiency.

Industrial Applications of Laser Nozzles

The Laser Nozzle is a critical component across multiple laser-based manufacturing applications:

Laser Cutting: Provides precise gas delivery to achieve clean cuts in metals, plastics, and composites.

Laser Welding: Maintains a protective gas shield to prevent oxidation and ensure smooth welds.

Laser Cleaning: Directs pressurized air or inert gas to blow away contaminants during surface preparation.

Laser Cladding and Additive Manufacturing: Controls gas flow to stabilize the molten pool and prevent oxidation of deposited materials.

From automotive to aerospace, from electronics to heavy machinery, the laser nozzle ensures that the beam maintains its energy integrity and that the work environment remains clean and controlled.

The Evolution of Laser Nozzle Design

Advancements in laser technology have driven innovation in nozzle design as well. Today’s Laser Nozzles are engineered to meet the growing demand for higher precision and faster production speeds. Adaptive nozzles with built-in sensors can monitor gas flow and temperature, while intelligent nozzle systems automatically adjust standoff distances during complex contour operations.

Some advanced nozzles even feature anti-collision designs, which protect the laser head from accidental impact during automated cutting or welding. Coated nozzles with anti-adhesive layers are also becoming common, reducing the need for frequent cleaning and improving long-term reliability.

Selecting the Right Laser Nozzle

Choosing the correct Laser Nozzle depends on multiple factors: laser type (fiber, CO₂, or diode), material thickness, desired cutting or welding quality, and assist gas type. Manufacturers often provide guidelines or compatibility charts to help users select the correct diameter and geometry for their specific laser head.

A nozzle that’s too small may restrict gas flow, while one that’s too large may lead to turbulence and loss of precision. Balancing these parameters ensures the laser system operates efficiently and produces consistent results.

Final Thoughts

The Laser Nozzle is much more than a simple metal component—it’s the bridge between laser power and material precision. It determines how effectively the laser energy and gas interact with the workpiece, influencing quality, speed, and overall system reliability.

In professional manufacturing environments, investing in high-quality laser nozzles and maintaining them properly translates directly into cleaner results, longer equipment life, and reduced downtime. Whether you’re cutting thin stainless sheets or welding thick steel plates, the right laser nozzle ensures your process stays stable, efficient, and precise every time.